Machined components

Copper-Burton offers standard and custom CNC-Milling, CNC-Lathe, Screw-machine, and Wire/Sinker EDM services. We have extensive experience with a wide range of materials including, but not limited to:

Aluminum,

Polycarbonate,

Delrin,

Graphite,

Kovar,

Molybdenum,

Monel,

Inconel,

Nickel,

Nitronic,

Stainless Steel 303, 304, 316, 416, 430

Titanium

QUALITY

Copper-Burton is committed to manufacturing high quality products from quotation through purchase order and production to delivery. Copper-Burton can offer you flexibility at every step of the process to meet your needs. Our mechanical engineers provide assistance to help you realize your ideas utilizing the latest 3-dimensional designing software.

Facilities

Copper-Burton manufactures with the best brand of production machinery and inspection equipment available in the market. We have production capabilities in both the U.S. and Southern China.

inspection

We perform in-house inspection to industry standards per the request of our customers.

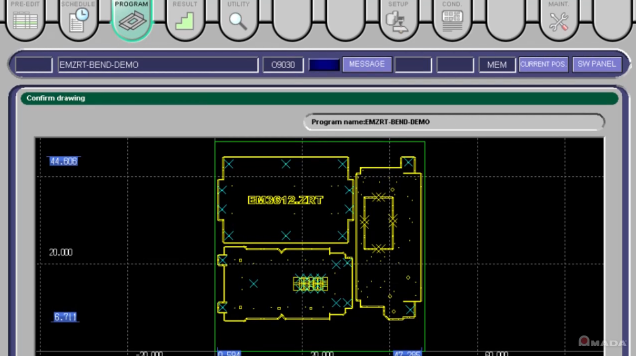

Programming:

- GEOPath Power CAD / CAM 3D Capable

- AUTOCAD

- Solidworks

- Surfcam

- Mastercam

Parts are inspected with the following equipment:

- Mitutoyo BRM 507 CMM

- 28" (X) x24" (Y) x18" (Z)

- Mitutoyo Bench Center 0-24

- Mitutoyo Optical Comparator PH-305A

- Mitutoyo Microscope (10x-20x)

- CMM Software: Latest version of the CMM Manager

engineering

Copper-Burton provides advanced CAD/CAM design and programming and has reverse engineering capabilities to turn your concept into prototype.

Our mechanical engineers provide technical expertise utilizing the latest 3-dimensional designing software.

We perform all of our engineering services on 2 GHz Pentium 4 computers running:

GEOPath

Power

CAD/CAM 3D Capable

AUTOCAD 14

Esprit CAM System

MACHINED COMPONENTS SHEET METAL CABLE ASSEMBLY RF CONNECTORS PCBA INJECTION MOLDING